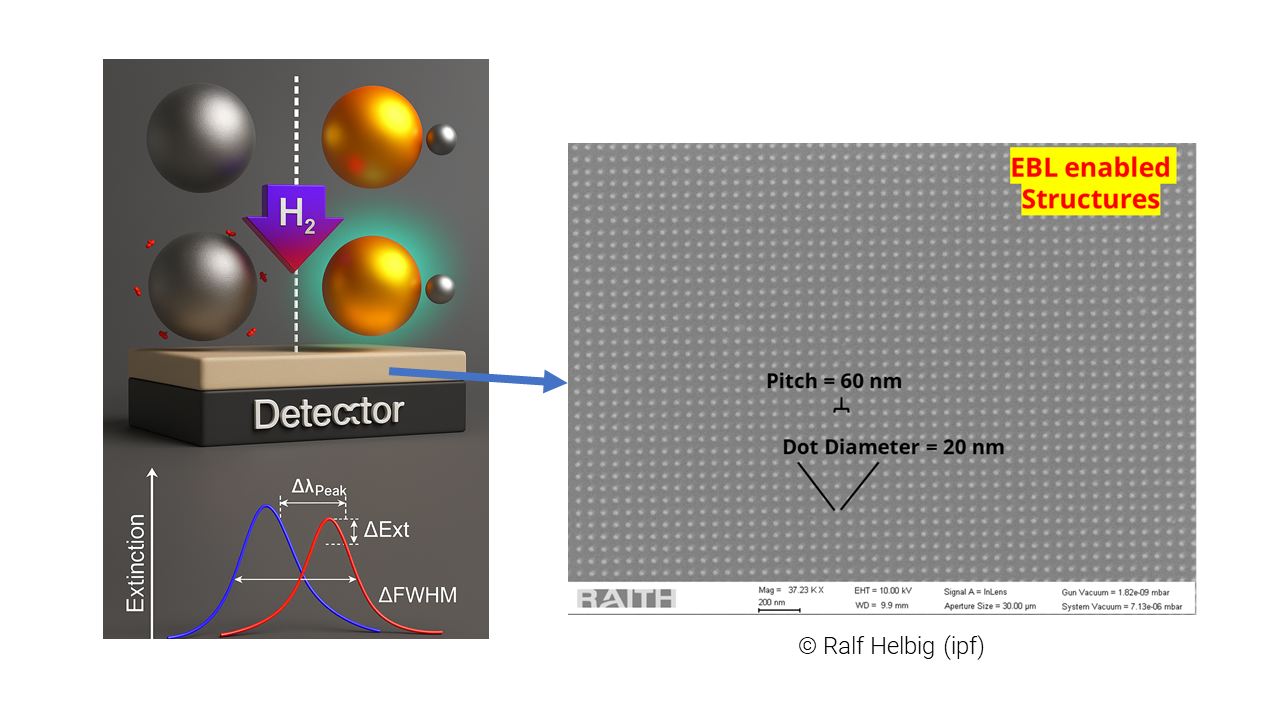

Hydrogen is a clean energy carrier, but it’s also highly flammable—meaning reliable leak detection is essential for safe industrial use. Traditional hydrogen detectors often struggle to detect very low concentrations (parts per billion) quickly and accurately, especially in complex industrial environments. These detectors suffers from flicker noise upon cyclic utilization. This project focuses on developing plasmonic sensing surfaces—nanostructured metallic films or nanoparticles that change their optical properties when exposed to hydrogen. By engineering the surface geometry and chemistry, we aim to achieve ultra-sensitive, fast, and selective hydrogen detection. Depending on your interests, you could work on fabricating the plasmonic surfaces, testing their sensing performance, optimizing their selectivity, or even integrating them into a small prototype detection system.

Scope of Work (Adaptable to Duration & Background)

1- Literature review on hydrogen detection methods, plasmonics, and nanostructured surface fabrication.

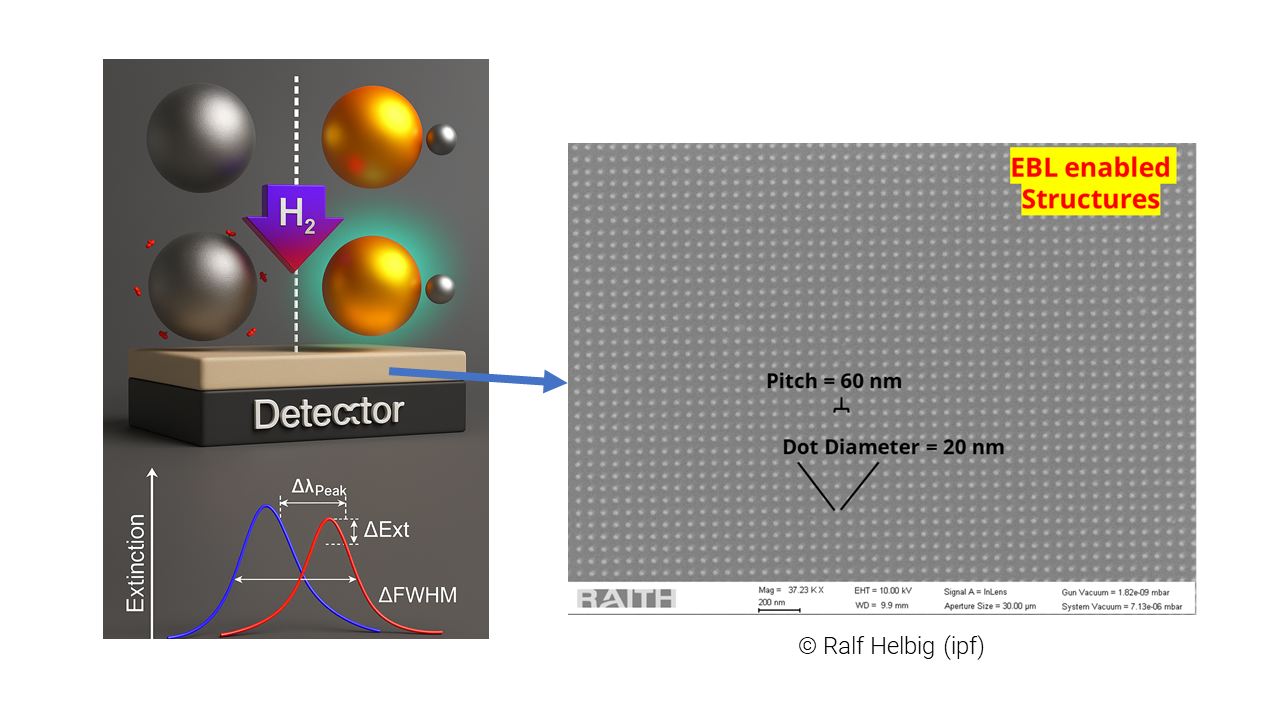

2- Design and fabrication of plasmonic surfaces (e.g., gold or palladium nanostructures, thin films, nanoarrays).

3- Surface functionalization to improve hydrogen selectivity and stability in industrial gas mixtures.

4- Optical characterization (UV–Vis spectroscopy, localized surface plasmon resonance shifts) under varying hydrogen concentrations down to the ppb range.

5- Sensor performance testing: sensitivity, selectivity, response time, and long-term stability.

6- Data analysis: signal processing for enhanced detection accuracy, optional machine learning approaches for pattern recognition.

7- Optional extended work: integration into a portable optical readout device for real-time hydrogen monitoring.

Adaptable project scale:

- Lab rotation (weeks) → Measurement and performance characterization only.

- Project work (2–3 months) → Fabrication plus basic hydrogen detection testing.

- Master’s/Diploma thesis (6+ months) → Full development cycle from design to prototype validation in simulated industrial conditions.

Hydrogen is a clean energy carrier, but it’s also highly flammable—meaning reliable leak detection is essential for safe industrial use. Traditional hydrogen detectors often struggle to detect very low concentrations (parts per billion) quickly and accurately, especially in complex industrial environments. These detectors suffers from flicker noise upon cyclic utilization. This project focuses on developing plasmonic sensing surfaces—nanostructured metallic films or nanoparticles that change their optical properties when exposed to hydrogen. By engineering the surface geometry and chemistry, we aim to achieve ultra-sensitive, fast, and selective hydrogen detection. Depending on your interests, you could work on fabricating the plasmonic surfaces, testing their sensing performance, optimizing their selectivity, or even integrating them into a small prototype detection system.

Scope of Work (Adaptable to Duration & Background)

1- Literature review on hydrogen detection methods, plasmonics, and nanostructured surface fabrication.

2- Design and fabrication of plasmonic surfaces (e.g., gold or palladium nanostructures, thin films, nanoarrays).

3- Surface functionalization to improve hydrogen selectivity and stability in industrial gas mixtures.

4- Optical characterization (UV–Vis spectroscopy, localized surface plasmon resonance shifts) under varying hydrogen concentrations down to the ppb range.

5- Sensor performance testing: sensitivity, selectivity, response time, and long-term stability.

6- Data analysis: signal processing for enhanced detection accuracy, optional machine learning approaches for pattern recognition.

7- Optional extended work: integration into a portable optical readout device for real-time hydrogen monitoring.

Adaptable project scale:

- Lab rotation (weeks) → Measurement and performance characterization only.

- Project work (2–3 months) → Fabrication plus basic hydrogen detection testing.

- Master’s/Diploma thesis (6+ months) → Full development cycle from design to prototype validation in simulated industrial conditions.